At LASTWOLF, crafting a varsity jacket isn’t just about stitching fabric together—it’s a journey rooted in tradition, craftsmanship, and attention to detail. Every jacket tells a story, and in this series, we’ll take you behind the scenes to show you exactly what goes into making one of our iconic pieces.

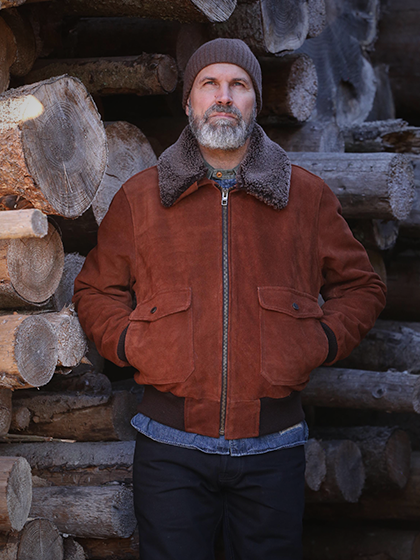

Choosing the Right Materials

It all starts with selecting the finest materials. Our team sources high-quality wool for the body of the jacket, ensuring durability and warmth. The leather sleeves, whether crafted from genuine cowhide or lambskin, are chosen for their softness and longevity. Every element, from the ribbed cuffs to the inner lining, is carefully selected to provide the perfect blend of style and functionality.

Precision in Design

Once the materials are selected, our design team meticulously sketches and refines each jacket’s blueprint. We focus on achieving the perfect fit—balancing comfort with a tailored look. Attention to detail is paramount, from the placement of the signature LASTWOLF embroidery to the customization options available to our customers.

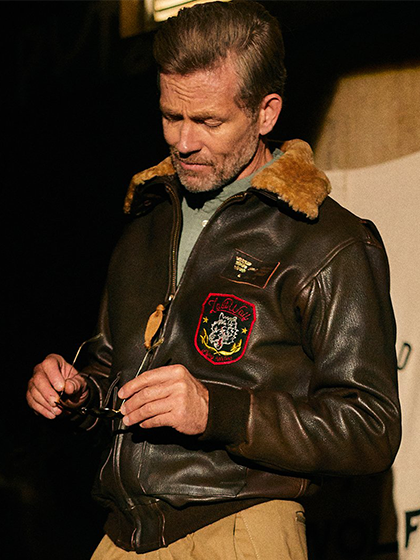

Craftsmanship at Its Core

Our artisans, with decades of experience, bring the design to life. Each panel is cut with precision, ensuring every piece fits seamlessly. The sewing process requires expert hands, combining traditional techniques with modern precision to achieve the highest quality standards.

Personalization and Customization

A varsity jacket is more than just a garment—it’s a statement. That’s why we offer extensive customization options, allowing you to choose colors, patches, and embroidery that reflect your personality. Whether you’re looking for a classic, vintage look or a modern twist, we’ve got you covered.

Quality Control and Final Touches

Before any jacket reaches your hands, it goes through rigorous quality control. Every stitch, button, and fabric panel is inspected to ensure it meets our exacting standards. Once approved, the final touches—such as steaming and packaging—are applied to make sure your jacket arrives in perfect condition.

Stay tuned for Part II, where we’ll dive deeper into the final assembly and finishing process that brings our varsity jackets to life.